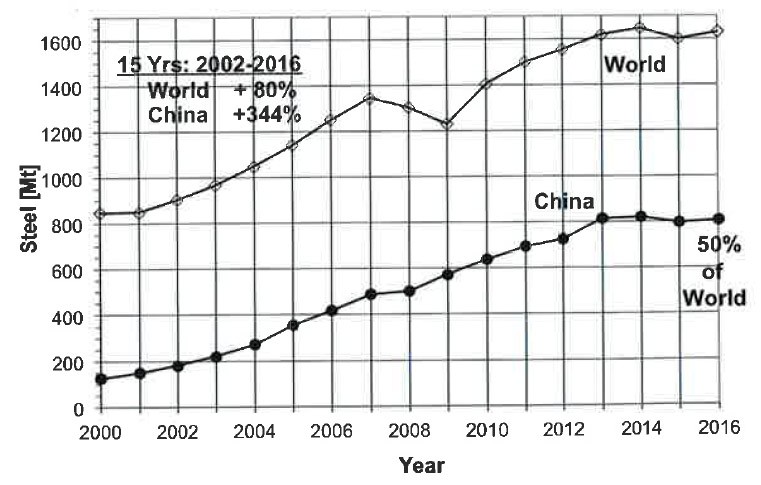

Globally, the major markets for refractories are iron and steel (~70%) and cement (~10%). The annual production of steel and cement, by the World and China, since 2000, as a general indication of the market trend for refractories. For both steel and cement production worlwide, and in China, it is seen thar the upward trend of many years has slowed/flattened over the las 2-3 years.

Jun 26

Refractory Products, the TC Refractories Perspective

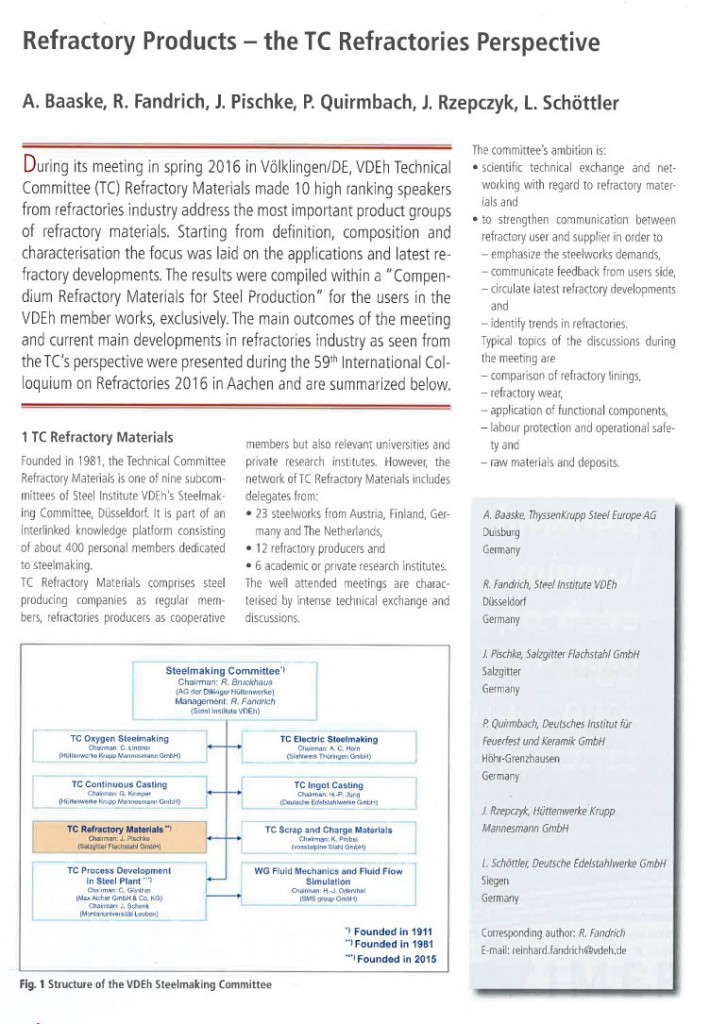

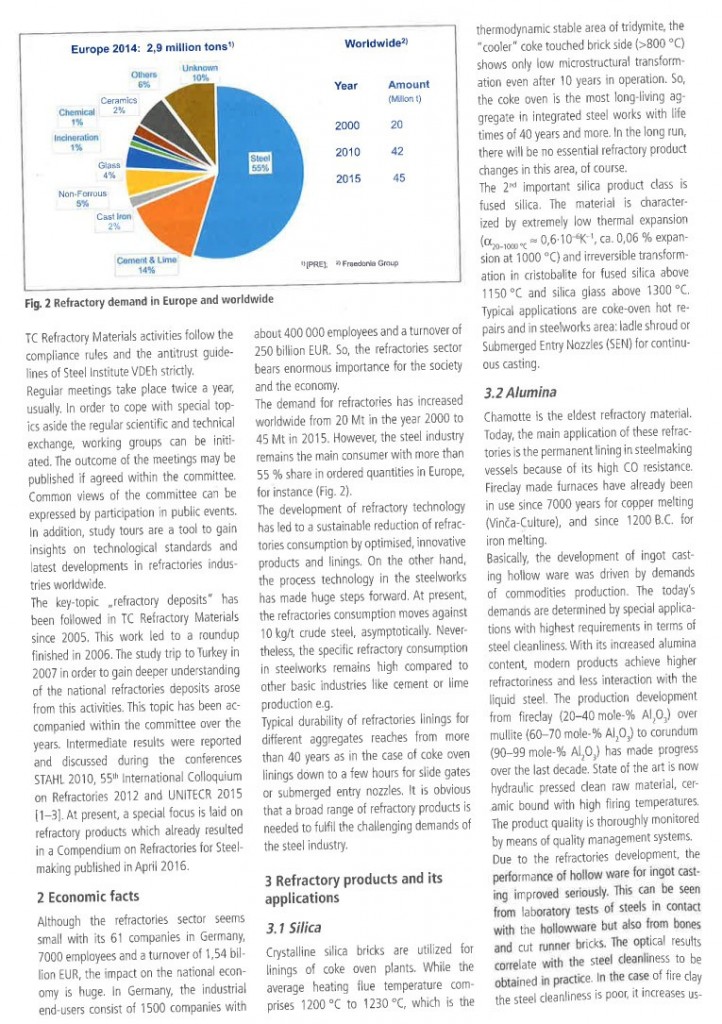

During its meeting in spring 2016 in Völklingen/DE, VDEh Technical Committee (TC) Refractory Materials made 10 high ranking speakers from refractories industry address the most important product groups of refractory materials. Starting fron definition, composition and characterisation the focus was laid on the applications and latest refractory developments …

Jun 19

Supply shortage pushes Chinese bauxite prices higher again

Chinese bauxite spot prices increased again in May as the ongoing anti-pollution related production shutdowns caused severe shortages in the market.

Refractory-grade bauxite spot prices jumped 18 May, as the ongoing massive production shut downs in China led trades to be concluded at higher values higher for the second time in May.

The anti-pollution controls in China have increased since the beginning of May, with Beijing shutting down most bauxite mines in Shanxi and Guizhou province, while calcining and processing plants in Shanxi and Tianjin were also impacted.

Only a minority of facilities that meet the strict environmental standards are allowed to continue production, but raw bauxite supply remains scarce due to current mining restrictions, market participants told IM.

«The whole system is choked, the supply is cut,» one US-based trader told IM.

«We have a bottleneck in Shanxi, we have no raw material, all the kilns are not running….Guizhou also more or less same situation,» another Europe-based trader agreed.

Following a price increase in early May, China-origin bauxite’s values rose again over the past two weeks amid reduced supply, according to IM’s assessment of the market on 18 May.

Prior to 2017, bauxite prices were depressed for the past few years amid oversupply and weak demand.

Spot prices of 85% refractory-grade bauxite (85% Al2O3/2.0/3.15-3.2/0-6mm) rose to $330-340/tonne on a FOB Xingang basis, while 86% bauxite increased to $340-350/tonne, both grades gained $10/tonne compared to previous assessment on 4 May.

As supply for higher-grade material, above 86% Al2O3 content, was even scarcer, 87% and 88% bauxite were trading at a higher premium in the market.

87% bauxite jumped to $390-420/tonne, up an average of $47.50 compared to a fortnight ago, while 88% was assessed at $420-440/tonne, both on FOB Xingang basis 18 May.

Only one supplier was reported to hold stock for the 87% bauxite in the market and bigger volume trades to refractory makers were concluded at $390/tonne while smaller lot sizes were sold at the higher range, according to the supplier and one Tianjin-based trader.

The output disruption in China has also caused shipment delays. At least two refractory makers in Asia and Europe reported delivery delays of up to one month.

Amid the severe supply shortage in China, producers elsewhere are reportedly receiving more enquiries.

But production elsewhere would not be able to replace lost output from China, market participants told IM.

While there is no official export data, one Europe-based distributor claimed China exported up to one million tonnes of bauxite in 2016, with shipments to Europe, Turkey and North Africa accounting for half the volume. While another Europe-based trader estimated Europe imports about 350,000 tonnes of bauxite from China.

Jun 12

China’s bauxite mining issues to hit brown fused alumina

Brown fused alumina (BFA) prices were unchanged over the fortnight, but market sources warned that new bauxite mining restrictions in China could impact BFA production in the near-term. BFA operations remained intermittent due to the ongoing environmental inspections.

The new spate of environmental crackdowns on bauxite mining in China is set to reduce raw material supply for brown fused alumina production in the country, market participants told IM.

Key refractory-grade bauxite producing region Shanxi has announced new environmental measure on 4 May to restrict mining and smelting activities in the province, as part of the implementation of the «Soil Prevention Action Plan». Under the plan, any expansions in the non-ferrous smelting industry around residential, school, medical and retirement home areas will be prohibited.

Furthermore, there will be strict assessments on the environmental impact of a number of polluting industries, including non-ferrous metal mining and smelting, chemical, coking, electroplating, tanning, pesticides, lead-acid battery production and others. Applications for the above sectors will require evidence on the environmental impact on soil and on pollution control.

According to a number of Chinese and Europe-based suppliers, the majority of mining activities in Shanxi have stopped, while calcining and processing plants in nearby Tianjin were also impacted. Only a small number of bauxite production facilities that meet the required environmental standards are allowed to operate, two Chinese suppliers and two Europe-based distributor told IM.

Although the reduced bauxite supply has yet to impact brown fused alumina (BFA) production, one Europe-based distributor warned that less raw material will affect the sector, thus supporting prices.

Furthermore, ahead of the 13th National Games of China, due to be held in Tianjin and Luoyang, Henan in September, authorities have ramped up efforts to clean up the local environment. This will impact brown fused alumina production in Henan, suppliers in China and Europe said.

China is the biggest fused alumina producer globally, with Henan province being the main producing region. Output in the province has been intermittent since July 2016 due to the ongoing environmental inspections.

BFA spot prices were unchanged over the past two weeks but high-quality material from Tipping furnace was scarce, two traders said.

Spot prices for Chinese-origin refractory grade BFA remain at $550-600/tonne on a FOB China basis, compared to a fortnight ago, according to IM’s assessment on 4 May.

Lower-grade BFA (minimum 95% Al2O3 and maximum 1.2% silica) produced from fixed or Higgins furnace was offered at $550/tonne while the higher-grade material of 0.9% silica content produced from Tipping furnace would be more expensive, one Tianjin-based trader said.

«Tipping furnace material is not so easy to find; it requires cash payment,» the Tianjin-based trader said.

The Europe-based distributor warned: «If anybody has bought anything for less than $580/tonne since 1 April, they may not get delivery.»

Jun 05

Massive production shutdown in China lifts bauxite prices

China-origin refractory-grade bauxite prices have increased for the second time this year as the government ramped up efforts to reduce pollution. Only a tiny minority of plants is still allowed to operate following the environmental inspections, and traders are struggling to find material to fulfil contracts.

Near-complete shutdown of Chinese refractory-grade bauxite production has lifted spot prices for the second time this year, with many traders struggling to fulfil contracts following further environmental crackdowns.

The ongoing anti-pollution controls in China have worsened over the past two weeks, with Beijing shutting down most bauxite mines in Shanxi province, while calcining and processing plants in Shanxi and Tianjin were also impacted.

Only a minority of facilities that meet the strict environmental standards are allowed to continue production, but raw bauxite supply remains scarce due to current mining restrictions, two Chinese producers told IM.

«Problems, problems everywhere I look. The situation in China is getting worse by the day,» one European trader told IM.

«Everybody has been stopped. Nobody is producing because of the environment [team] running around. They are going from plant to plant. They will suspend production until September,» he added.

It is unclear for how long such strict environmental measures will remain in place but many are anticipating the policy to be long-term, as tackling pollution has been identified as as a top priority in 2017 for Beijing.

Following a first round of controls since July 2016, many bauxite production facilities that did not meet the state required standards were shut down.

But ahead of the 13th National Games of China, due to be held in Tianjin and Luoyang in September, authorities have ramped up efforts to clean up the local environment, market participants in China and Europe said.

The local government in Shanxi has rolled out new environmental policies in early May to tackle the pollution caused by local industries, including refractory minerals production.

China-based suppliers spoke of a wide-spread, «crazy» shutdown of facilities that did not meet the environmental requirements.

«Foreigners said it is crazy now in China. We Chinese think so too, but what can you do if the country wants to sort itself out?» one Tianjin-based supplier said.

According to one Chinese supplier, all Chinese plants (factories producing all sorts of products, including bauxite, magnesia and brown fused alumina), have to implement the following:

All operation can only rely on gas or and electricity for energy supply, as no coal or coke is allowed. Plants have to install an external on-line system to monitor dust control, and also to install a monitoring system for flue gas de-sulphurisation in the plants.

«If the three [parameters are not met], the plants [will be] closed until they do. This time it’s not a joke, the government is really doing it,» he added.

Shanxi accounts for the majority of refractory minerals production, supplying most of calcined bauxite in the world, according to market sources.

Earlier this week, IM has reported on the worsening output disruption in magnesia producing region in Liaoning, which is also part of Beijing’s crack down on polluting industries.

Due to the clampdown on mining and smelting industries over the past two weeks, bauxite supply has reduced dramatically, supporting price upticks.

All refractory-grade bauxite prices have increased by $10/tonne over the past fortnight, according to IM’s assessment on 4 May.

Spot prices of 85% refractory-grade bauxite (85% Al2O3/2.0/3.15-3.2/0-6mm) rose to $320-330/tonne on a FOB Xingang basis, while 86% bauxite increased to $330-340/tonne, 87% edged up to $350-365/tonne and 88% climbed to $380-400/tonne.

Supply for higher-grade material, above 86% Al2O3 content, is even tighter, with very little trades reported as buyers were unable to source, according to three traders and one producer.

High-risk business

Furthermore, any spot business for China-origin bauxite would now require full pre-payment before delivery, and there is a high risk that suppliers could still not fulfil the contract, traders said.

«You can’t trust them even if they tell you they have material,» said one European trader.

Another European distributor and Chinese supplier agreed, saying that there is the possibility that the material delivered may not meet the agreed specifications and suppliers could fail to honour contractual agreements at the last minute.

«[The situation] is changing by the minute. The next moment they could say they can’t deliver the stock,» said one Tianjin-based supplier.

Still, many buyers run the risk of missing out on deals if they do not comply with the new cash-payment term. One Europe-based distributor said: «They have to pay quickly. If they don’t pay quickly, the suppliers will sell to someone else.»

Despite the higher prices, many are still struggling to find materials to fulfil annual contracts for 2017, while one Europe-based refractory producer was experiencing delivery delays in April, according to buyers.

The extreme shortage in bauxite supply in the past month has been compounded by some Europe-based traders selling short – agreeing to annual contracts with their customers in end-2016 without securing supply in advance, as they believed prices will remain low due to oversupply, the Europe-based distributor said.

«The problem is all these traders were selling short (…) This is caused by lots of traders who were speculating,» he said.