Dalmia-OCL hails an increase in its clean refractory capacity after buying German GSB group.

Indian refractory producer Dalmia-OCL has expanded into Europe with the purchase of Germany specialty refractory manufacturer GSB Group GmbH, increasing its stake in the clean refractories market.

The transaction was valued at €15 million ($17 million), Fastmarkets IM has learned.

According to Dalmia-OCL the investment will be funded partially by internal accruals and debt.

«This acquisition will […] make us one of the specialized manufacturers of refractories for cleaner steel production, a focus area for Indian steel makers,» Dalmia-OCL chief executive officer Sameer Nagpal.

GSB Group operates two production sites at Bochum in Germany and Bhilai in India. Dalmia- OCL refused to share the installed capacity of these two acquired plants.

In 2018, Dalmia-OCL signed a joint venture with Slovenian refractory company Seven to produce advanced monolithics in India. Dalmia-OCL has a 51% stake in this joint venture.

Dalmia-OCL is India’s second-largest refractory company with a production capacity of 250,000 tonnes per year.

Currently, Dalmia-OCL operates five refractory production plants (four in India and one in China) with an installed capacity of 250,000 tpy of refractory products.

The company expects to close the current financial year (April 2018- March 2019) with a revenue of 8 billion rupees ($111 million).

In its domestic market, Dalmia-OCL has been working on readjusting its product portfolio by focusing on the production of high performance bricks for cement kilns and special quality bricks for high purity steel.

The company is also looking for alternatives for magnesia bricks to hedge against uncertainties in raw material availability.

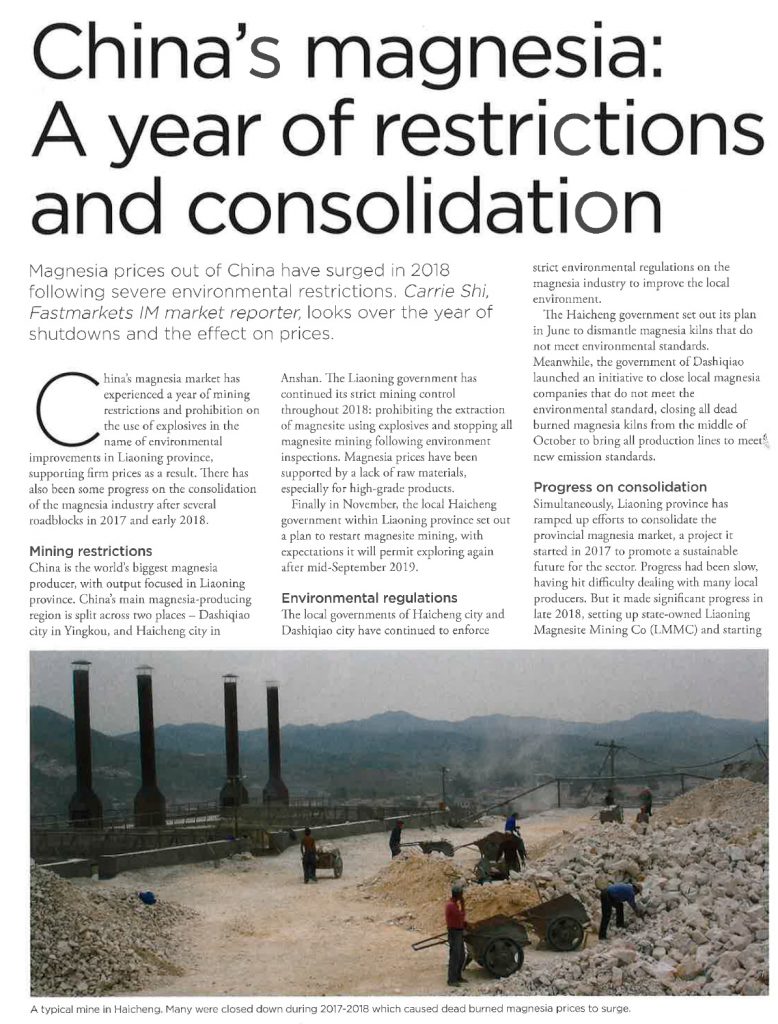

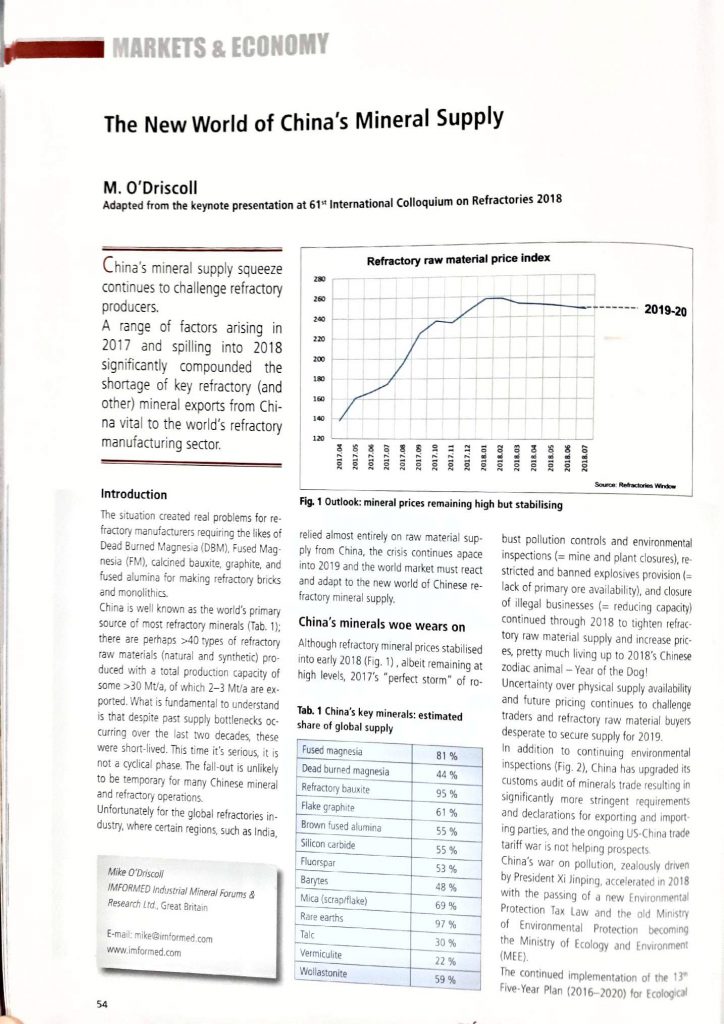

Chinese magnesia prices have tightened over the long term, although prices are down from the their 2018 peak.

Fastmarkets’ February 5 price assessment for fused magnesia,basis 97% MgO, Ca:Si 2:1, lump, fob China, was $1,250-1,350 per tonne. This was up from $440-445 per tonne in July 2017, but down from $1,600-1,800 per tonne at the start of 2018.